Sfmoma

Snohetta

Sector

Public museum

Location

151 3rd street,

San Francisco

Year

2013-2015

Designer

Snohetta

Architects

Snohetta

Client

San Francisco Museum of Modern Art

Building completion

2016

Area

235 000 sqm

Sustainability

LEED gold

In San Francisco, they experience

long and comfortable summers.

The winters are short, wet, cold and partly cloudy.

Over the year, the temperature varies from 45 to 72 degrees Fahrenheit and

is rarely below 39 degrees Fahrenheit. Hence, Sfmoma Snohetta has a double skin facade to buffer the heat in the summer while retaining heat in the winters.

Facade Concept

The façade is inspired by the ripples of San Francisco waterfront and the vibrant streetscape in the distance.

The image reflected the concept of the designers' intent. In contrast to the general vertical pattern of the buildings surrounding, the ripples flows smoothly on the façade, giving a sense of lightness against the site context.

Facade Sustainability

The Fiber-Reinforced Polymer (FRP) panels envelopes the façade with an area more than 5000 sqm, making it the largest FRP façade made to date in USA. To obtain building permit, it

successfully passed all the fire regulation tests that is obligatory if FRP is to be used above fourth storey level on a high rise exterior.

This facade is lightweight, cost saving and requires a short

construction period, hence it is a sustainable solution.

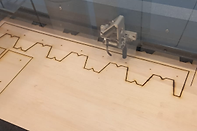

As part of a group assignment, we were tasked to research the detailing behind how the FRP panel were being

supported onto the secondary structure of the building in relation to the primary structure and floorslab. This diagram is done in CAD, the detailing is replicated to the best of our belief of how the FRP panel is cladded to the facade. Based on this, we have to make a 1:2 physical

model to show the detailings.

Facade Detailing

Fabrication Process

The fabrication process involves

+ 3D printing

+ Laser cutting

+ Hand cutting

+Spray Painting

Through this making process, we learnt valuable skills in AutoCAD,

detailing, sourcing of materials, software modelling, working with teammates and coordination skills. It was a daunting task with a tight deadline and although we struggled a lot, the takeaways and the end result

exceeded our expectations and we take pride in our work.